Build the Perfect Tool for Your Needs

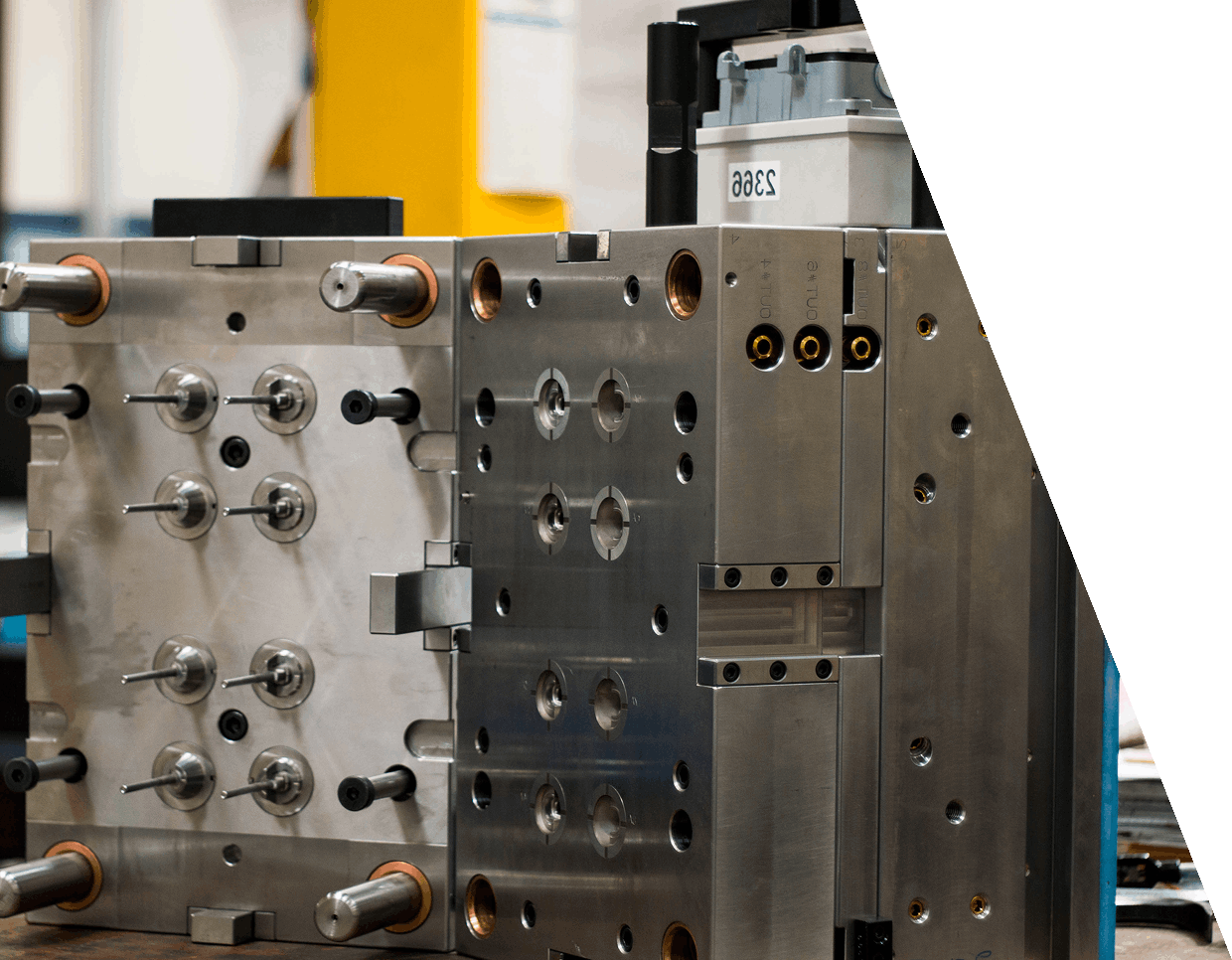

The success of your injection moulding project starts with high-quality tooling. With 30 years of industry expertise, Philip John Schoofs provide comprehensive tooling consultancy services to ensure optimal performance, durability, and cost efficiency. From tooling design to selecting the right toolmakers, we guide you through every step to achieve seamless production and superior product quality.

Our Tooling Services

Managing the construction of injection moulding tools requires technical expertise and precision. We oversee the entire process, ensuring that your tools are built to high-quality standards, meet production requirements, and are delivered on time and within budget.

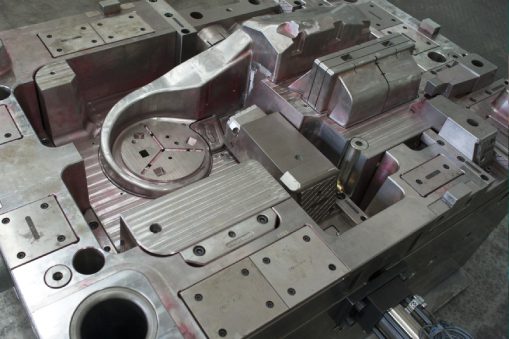

A well-designed tool is crucial for consistent and efficient production. Our Design for Manufacture (DFM) review ensures that your tooling is optimised for:

- Longevity & durability

- Cost-efficient manufacturing

- Precision & repeatability

- Faster cycle times

Not sure if your tool design is efficient? Our experts assess your tool layout, material selection, cooling channels, and ejection systems to eliminate potential defects and enhance performance. We help prevent warping, sink marks, and production inefficiencies before they become costly issues.

Choosing the right toolmaker is critical for quality and longevity. We help you identify, evaluate, and select the best toolmakers based on:

- Material & craftsmanship quality

- Production capabilities & lead times

- Cost efficiency & long-term reliability

Expert Injection Moulding Tooling Solutions

Do you have questions or need expert guidance? The best way to reach us is by email or phone. We’re here to help with all your injection moulding tooling needs.