Simplify Injection Moulding From Start to Finish

We Manage Tooling, Sourcing, and Suppliers for a Smooth, Efficient Process

Professional Tooling and Injection Moulding

Project Management

30 Years of Industry Experience

Mastering injection moulding processes & tooling optimisation.

End-to-End Expertise

From concept to commercialisation, we manage the entire process.

Precision & Quality Focus

Delivering cost-effective and high-performance solutions.

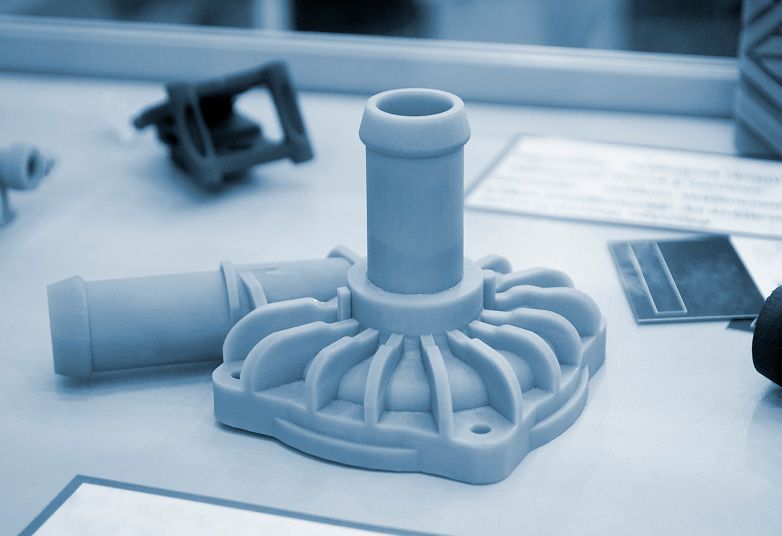

Expert Injection Moulding Solutions

With decades of expertise in injection moulding, Philip John Schoofs specialises in managing the complexities of tooling, design, and supplier selection. From concept to commercialisation, we provide end-to-end solutions that ensure efficiency, precision, and quality in every project. Our focus is on delivering cost-effective, high-performance results for businesses seeking excellence in plastic product manufacturing.

What We Offer

Tool Sourcing & Selection

We connect you with trusted toolmakers to ensure precision, durability, and efficiency in mould development.

Product & Tool Design Review

Optimising your design for manufacturability, reducing costs, and enhancing performance before production begins.

Supplier Selection & Manufacturing Support

We help you identify and secure reliable injection moulding partners for long-term success.

Injection Moulding Part Sourcing

Ensuring quality, consistency, and supply chain efficiency for your plastic components.

Streamline Your Manufacturing

Maximise efficiency and quality with expert guidance in injection moulding. Whether you need tool sourcing, design optimisation, or supplier selection, we provide tailored solutions to ensure precision, durability, and cost-effectiveness. Let’s streamline your manufacturing process for long-term success.